In this post, my dad, Joe Karrick, reflects on his memories of stripping tobacco. As he notes, tobacco was once grown on almost every Kentucky farm. Indeed, data from the USDA shows that in the 1950s, Kentucky had around 136,000 working tobacco farms, but by 2022 that number had dropped to 984. That decrease came about due to the drop in demand because of increased health concerns over tobacco usage, and also because of a major reform signed into law in 2004, commonly referred to as simply “the buyout.” While tobacco growing may not be the thing it once was, it’s still important to know our history and the work that shaped and supported families for generations.

From my dad, Joe Karrick:

When I was growing up, about all farms in Kentucky grew some tobacco – we were no exception. We grew about 2 – 2 1/2 acres of tobacco every year. In the fall of the year, after the tobacco had cured in the big tobacco barn, it was time to “strip” it. This involved pulling the tobacco leaves off the stalks and tying the bundles of leaves into hands.

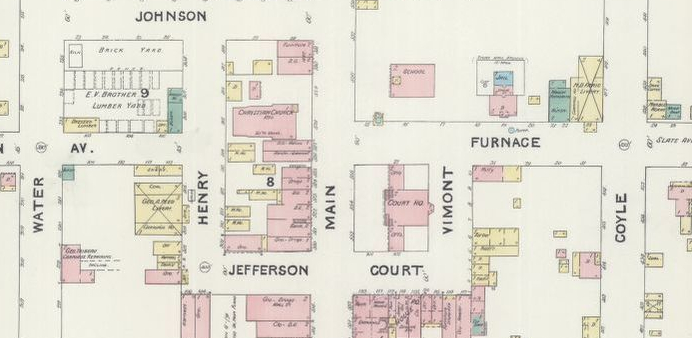

Tobacco had to be “in case” in order to work it. “In case” meant that the leaves had enough moisture in them to be pliable and workable. Rainy days and foggy mornings would bring tobacco in case. The sticks holding about 6 stalks of tobacco would be dropped down out of the barn rails. The stalks of tobacco would be pulled off the sticks and stacked tightly in a pile or bulk, and covered to retain moisture.

There was a “stripping room” attached to the barn on the north side. The entire north side of the stripping room was windows to give light to work by. Norther exposure was preferred because the light was not glaring and more stable throughout the day. A waist high table ran the entire length of the room, about 20 to 24 feet long. A small stove at one end heated the room.

Tobacco was brought into the stripping room a large arm load at a time and placed on the left end of the table. I remember my mom helping strip tobacco. She would strip the bottom leaves off the stalk, place the stalk on the table to the right, and my Dad would then pull the middle leaves off.

Tobacco had to be sorted into about 5 grades as it was stripped. My Mom would pull off the bottom damaged leaves called “trash” and pile them on the floor by her side. Then she would pull off the next grade of leaves, the “flyings” and accumulate them in her hand. Flyings were bright colored, usually tan-yellow with tattered edges. Dad pulled the “lug” leaves. Lugs grew in the middle of the stalk and were large, smooth, solid, tan/brown colored leaves, usually the most valuable. Above the lugs there would usually be two to three “bright” leaves. These were darker than the lugs and showed more red colors. Dad would pull them and make a pile on the floor by his side. He then passed the stalks down to me, and I would pull off the remaining leaves, the “Red.” Red leaves were shorter and darker colored than the Brights and Lugs. Empty stalks were piled on the right end of the table.

We accumulated the leaves in our hands until we couldn’t hold anymore. Then taking a leaf and folding it along the stem, we used it to tie the “hand” of tobacco to hold it together. The tie was made at the stem end of the leaves with all the stems bound tightly together. Thus a hand of tobacco was the quantity of leaves that you could hold in your hand.

The hands of tobacco were then placed on a tobacco stick – a stick would hold 12-14 hands. When the stick was full it would be “pressed.” The stick of stripped tobacco would be put in a press and squeezed flat and made easier to handle.

Work would continue all day; carry armloads of tobacco in, strip the leaves off, tie the leaves into hands, carry out the empty stalks, press the finished hands, place the finished pressed hands in a tight pile or bulk and cover.

We usually had a coffee pot on the stove and something for lunch, maybe beans, corn bread or some other basic grub.

We worked together toward a common goal. I learned early where money came from, and I learned the value of hard, honest work. I saw my mom and dad stick together through thick and thing – a good life lesson!

Sources: https://www.lpm.org/news/2024-10-22/crop-cashed-out-less-than-1k-ky-farms-still-grow-tobacco-20-years-after-major-reform and https://guides.loc.gov/tobacco-industry.

Thanks for reading!